Worldwide Foam operates 4 horizontal loop splitters in the United States, with a 5th unit being installed in our Silao, Mexico facility in 2021. Our Fecken-Kirfel skiving lines are capable of converting conventional XLPE bun stocks into long, continuous rolls. We would be pleased to customize roll thicknesses and lengths unique to your equipment, applications, and customer demands.

Depending on the size of your parts, tool layout or the width of your accompanying adhesive system, our team can suggest an alternative bun orientation to optimize your raw material yield.

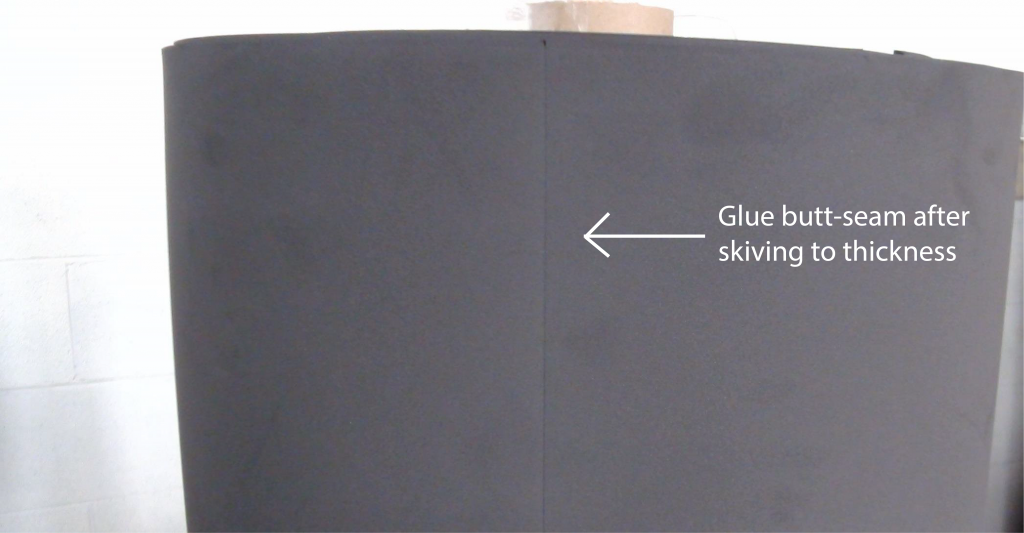

Our 2lb and 4lb XLPE looped rolls can be a great alternative to extruded XLPE roll stocks, due to our quick turnaround time, customizability, lower MOQs, and competitive costs. Traditionally, the dimensions of the extruded rolls are dictated by the width of the extruders and the size of the die. By converting bun stocks into custom rolls, the thickness, width, and length of the roll will not be limited by manufacturers. When converting XLPE buns into rolls, we butt-seam materials together using heat or glue. This process generates a “usable seam’, which for most applications is not a concern. An example of our seam can be found in the picture below. If our customers have defined cosmetic requirements that will not allow seams in their finish parts, not a problem. We have additional format options we can offer.

Additionally, our loop splitters are equipped with laser measuring sensors, providing critical measurement data throughout each run. This extra level of validation ensures we understand every foot of foam we produce.

Contact us for more details!