As a material supplier, we regularly discuss pricing with customers. Most purchasing agents are keenly aware of what their board foot cost is and use this as a basis of comparison amongst suppliers. While we won’t minimize its importance, we believe an equally important aspect of this is to maximize the efficiency of the material you do buy. In doing this, there are two important components when it comes to 2 dimensional CNC foam cutting.

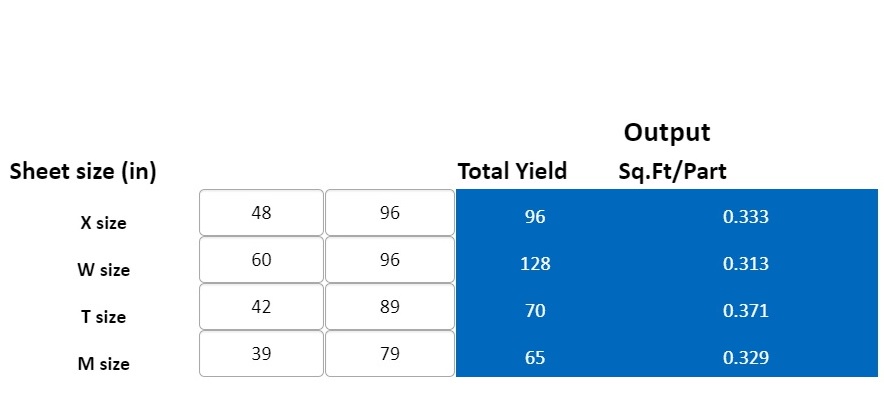

1. Choosing the right size of the material: Worldwide Foam offers 4 sizes in key densities to allow customers to maximize the yield efficiency. We have an easy online tool that allows you to do a simple analysis as to what size is right for what job. The output is in square foot per part to allow you to easily determine which size works the best. As an example below, a 3” x 15” part returns a 6% better return on a 60 x 96 versus the widely used 48 x 96. Repeated over and over, this type of savings can really add up.

2. Automatic nesting: This function is available on most CAD/CAM programs. By nesting multiple parts in like materials and thicknesses you can turbocharge your yields and improve the overall productivity of the shop floor. In addition, many of the more advanced software systems (Sigmanest, IGEMS) can squeeze further reductions in material use and cutting time by applying advanced cutting techniques.