As we reflect on another year, we’re grateful for your business and support. We wish you and your loved ones a happy and peaceful holiday season.

Highlights of 2024:

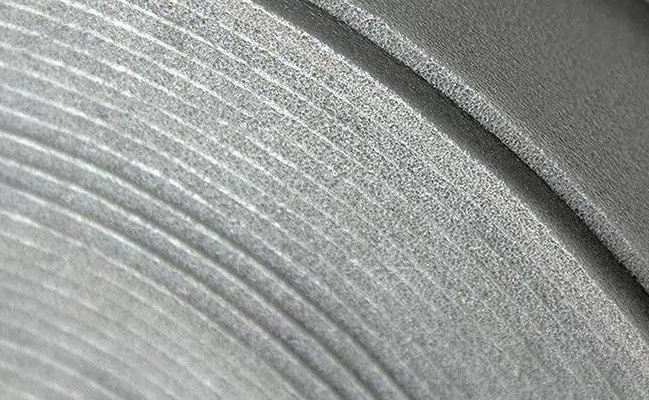

Extrusion line in Elkhart, IN: This new extruder allows us to produce chemically crosslinked polyethylene (XLPE) foam rolls in a wider range of densities (1.8-6 lbs/ft³), widths (up to 75″), and custom lengths. To further expand our production capacity, we’re adding a second extruder, which is expected to be operational in the third quarter of 2025.

Microsoft Dynamics ERP system: While there were temporary delays in communication and services during the transition period, we believe this change will enhance our customer service capabilities and lead to a better overall experience.

XLPE Recycle capability in Mexico: This is an expansion of our sustainability commitment to the Mexico Market. By recycling the scraps, our customers could free up floor space, save landfill and waste hauling costs. The foam scraps are ground up at our Silao Mexico facility and repurposed into multiple different applications such as sport turf and playground underlayment.

As we look ahead to 2025, we’re excited about the future and committed to continuing to be your one-stop shop for closed-cell foam solutions.

What’s New in Worldwide Foam

Extruded Crosslinked Rolls

Our popular extruded crosslinked roll goods (XE) are now made in Elkhart, Indiana!

EM-41

For those who are looking for 2A1 EPDM but not the premium price tag for automotive spec, the EM-41-ST and EM-41-UL are worth a second look.

What You Might Have Missed

Tolerances:

Explore the essential aspects of skiving tolerances in XLPE and PE foams. Our latest white paper covers terminology, methods, and key factors affecting thickness variations, along with how Worldwide Foam’s processes ensure precision for your specific application needs.