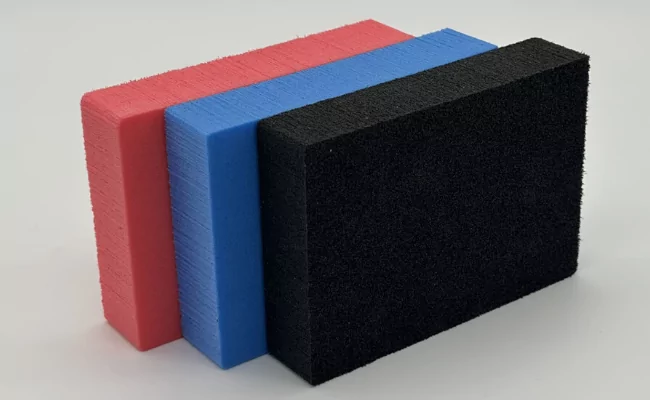

We have seen the increasing demand for precision tool control/shadow board applications.

To support the growing inquiries, we added a more advanced hot air laminator to our Elkhart facility last year.

The hot air laminator melts the foam surface using hot air blades, turning it into a tacky substance that acts as an adhesive and creates a permanent bond. The computer-controlled rollers allow us to achieve better edge alignment and more consistent bond, which directly translates to more usable materials.

Beyond tool control, this advanced laminating process is well-suited for any composite/laminated sheet project. We are also expanding our material options, adding more densities and colors to ensure we have the right materials for your needs.

Benefits that translate to your bottom line:

-

Increased efficiency by receiving composite sheets from us.

-

Better edge alignment to reduce waste and increase material yield.

-

Consistent bond to improve quality in every sheet.

-

Wide variety of density and color combo to enhance flexibility

For any composite/laminated sheets inquiries, contact us today!

What’s New in Worldwide Foam

WZ-40

We are thrilled to introduce our latest product offering the WZ-40, a 2.5lb/ft3 density, 1.375”x48”x80” XLPE foam.

PCORR

We now carry corrugated plastic sheets in 2, 3, 4 ,5 ,6, and 10mm x 48”x96” C. Blue and black are standard across the board. The 4mm is also available in white.

What You Might Have Missed

New Year, New Goals!

Welcome to the inaugural edition of 2024. We’ve turned the page on another year. We have many exciting plans for 2024, and we would like you to be part of it. Your insights are crucial in helping us shape the year 2024. Please take 30 seconds to fill out this 7-question survey.