The Fastest Growing Closed Cell Foam Supplier in North America

Worldwide Foam is the Leading Closed-Cell Cross-Linked Polyethylene Foam & Closed-Cell Elastomeric Foam Supplier.

Need Proof? Request a Sample Today!

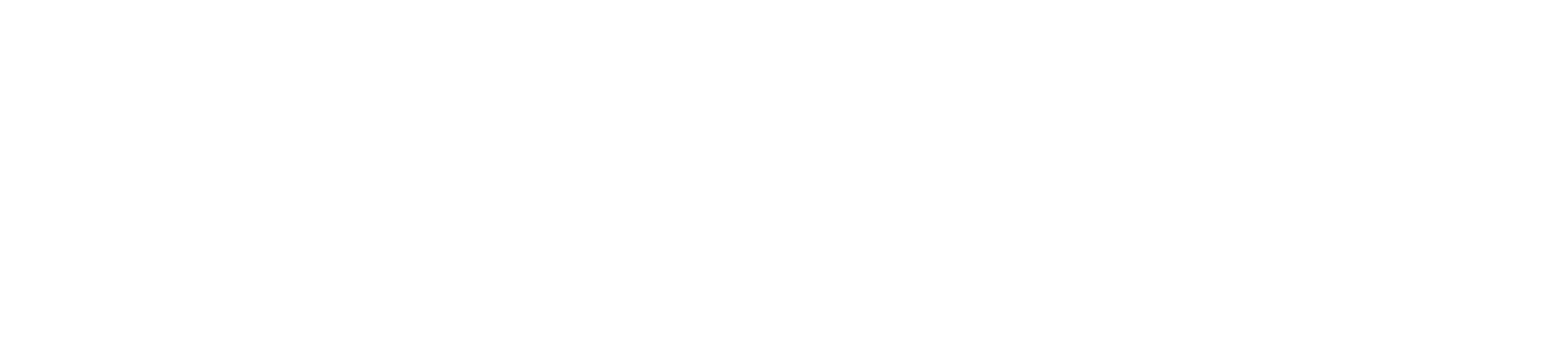

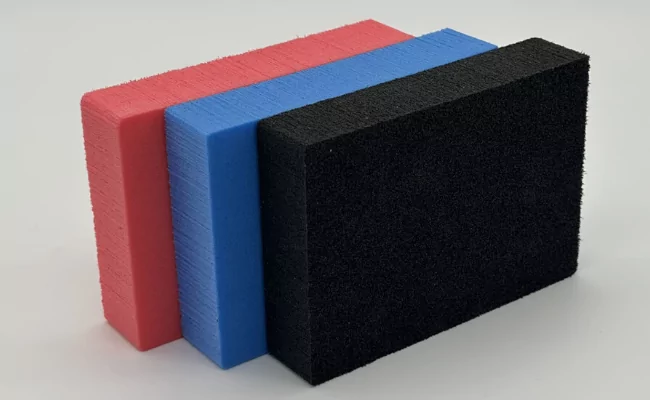

Featured Product

Introducing WZ-40, a 2.5 lb/ft3 density, 1.375" x 48" x 80" XLPE foam. WZ-40 builds upon the success of the popular WZ-30, offering fabricators a superiour solution for their diverse applications. Key features include: premium performance, vibrant colors, low VOC's and lightweight.

Featured Videos

Learn More About How Worldwide Foam Delivers Quality to Our Clients.

Featured Tools & Resources

Elastomeric Material Selection Tool

Use our selection tool to help engineers explore material options for the components in their designs.

Pressure Sensitive Adhesive Selection Tool

Worldwide Foam carries a multitude of Pressure Sensitive Adhesives (PSAs) in our inventory. This selection guide helps pick the best PSA for any project!

Managed Product Chart

Learn more about product specifications for all our products.

Latest News

April 2024 Product Spotlight: XEV-20

Versatile 2lb XLPE Originally developed for gym mat and flooring applications with higher VA content to increase compression deflection and tensile strength, the XEV-20 has found a new niche market that we didn't anticipate. With an ever-increasing demand for EV...

April 2024 Newsletter – Dock to Dock Advantage

Streamline Shipping & Save: Dock-To-Dock Advantage Tired of juggling multiple shipping providers? Our dock-to-dock program offers a one-stop solution that saves you time and money. Our dedicated logistics team is with you every step of the way. We handle any...

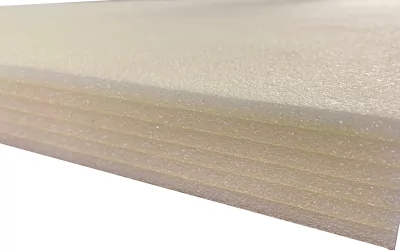

March 2024 Product Spotlight: 2A1 EPDM

EM-41st & EM-41UL For those who are looking for 2A1 EPDM but do not need the automotive spec, the EM-41-ST and EM-41-UL are worth a second look. With a nominal shore hardness rating of 39(00), the EM-41 series is a general purpose 4.93 lb/ft3 closed cell EPDM...

About Worldwide Foam

Most Diverse Closed Cell Foam Supplier In North America

Since 2008, we have revolutionized the industry by offering a one-day lead time from our seven strategic locations while providing the most comprehensive ranges of closed-cell cross-linked polyethylene and elastomeric foam in the world. We are constantly expanding our servicing capabilities to supply you with the best options for your press-ready goods.

Why Worldwide Foam?

Extensive Inventory

8 million board foot inventory with a wide range of sizes and densities

Customer Support

Ensuring our customers never have to worry about getting the product they need

Fast Turnaround

Multiple locations to reduce shipping costs and transit time to our customers

Add-On Services

A variety of services available to our customers as an added convenience

Customer Satisfaction Guarantee

Unbeatable Support.

With a relentless focus on providing closed-cell foam customers with the product they need when needed, Worldwide Foam ensures our customers never have to worry about having the product they need. And we are constantly expanding our servicing capabilities to supply you with the best options for your press-ready goods.

Same-Day Shipping.

One-day lead time from our seven strategic locations while providing the widest ranges of products and sizes in the industry.

Products & Services

Our Company

Elkhart, IN

La Porte, IN

Wurtland, KY

Atlanta, GA

Ontario, CA

Copyright ©2022. All Rights Reserved.